● Perfect watertightness

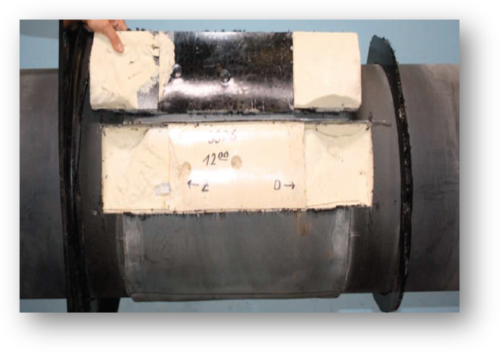

The joining of the connections is carried out by an electric fusion welding machine with built-in process software, and the final barometric pressure test is performed to confirm the perfect watertightness. The fusing temperature and time are automatically adjusted to achieve uniform quality and perfect bonding, while the entire fusion process is recorded and stored on the computer for feedback.

● Fast and safe construction

The electric fusion welding method using HDPE spacers and supports simplifies the welding process and reduces the installation time to a minimum. In addition, unlike the heat shrink casing method that uses LPG torch lamps, the EFW SYSTEM provides safe construction in fire hazard areas or confined working environments.

● Economic efficiency

Electric fusion products areproduced through a thorough quality control system during the production process. On-site construction is carried out in accordance with EN489 regulations, and a quality certificate is issued upon the customer's request. Semi-permanent service life and reduction of maintenance costs provide customers with efficient use of resources and economic benefits in the longterm.